With over 20 years of experience, the expert artisans at D.P. Juza Woods & Fixtures have mastered the techniques required to create pieces that hold up to the highest standards in our industry. Through trial and error, the lessons learned have served each and every craftsmen every day on the job. In the first of a continuing series of blog posts, those same craftsmen have offered to share some very useful woodworking tips, tricks, jigs and techniques.

The Trick

Whether it is custom retail fixtures, commercial cabinetry, residential kitchen cupboards or a finely detailed table, it is quite common for hardwood to be joined to sheet stock, creating a smooth and seamless finish along the edge. This process is used to give the piece a “finished look” to the edges and not exposing the “core” of the sheet stock. As an example, think of a rectangle table top that is made with wood veneered sheet stock and has solid wood around all 4 edges.

The trick is to be able to sand the wood edge AND the veneered sheet stock smooth without sanding or burning off the veneer and exposing the core of that sheet stock. Remember, the wood veneer that is on the sheet stock is very thin and can easily be sanded off if you are not paying close attention. Nothing will ruin a day more than over sanding and consequently ruining a work in progress because you sanded just a little too much. The solution? A pencil.

The Tip

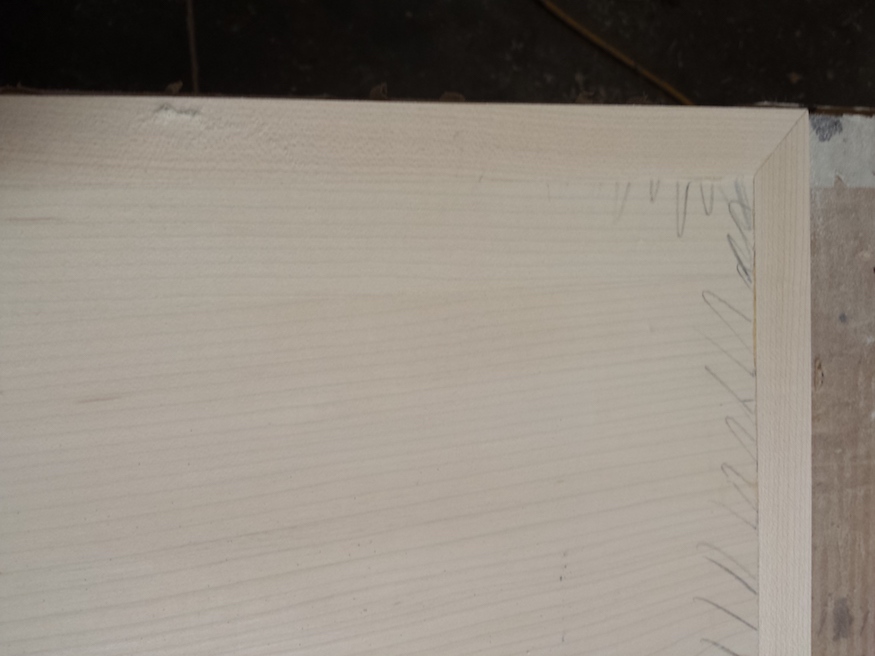

It is important to remember that when you are applying the wood edge to the sheet stock, you should NOT attach them so that the top of the wood is at the same level as the top of the sheet stock. The wood should be slightly higher, generally 1/64” to 1/32”. In other words, if you run your hand along the top and come to the edge, the wood should be sticking up ever so slightly.

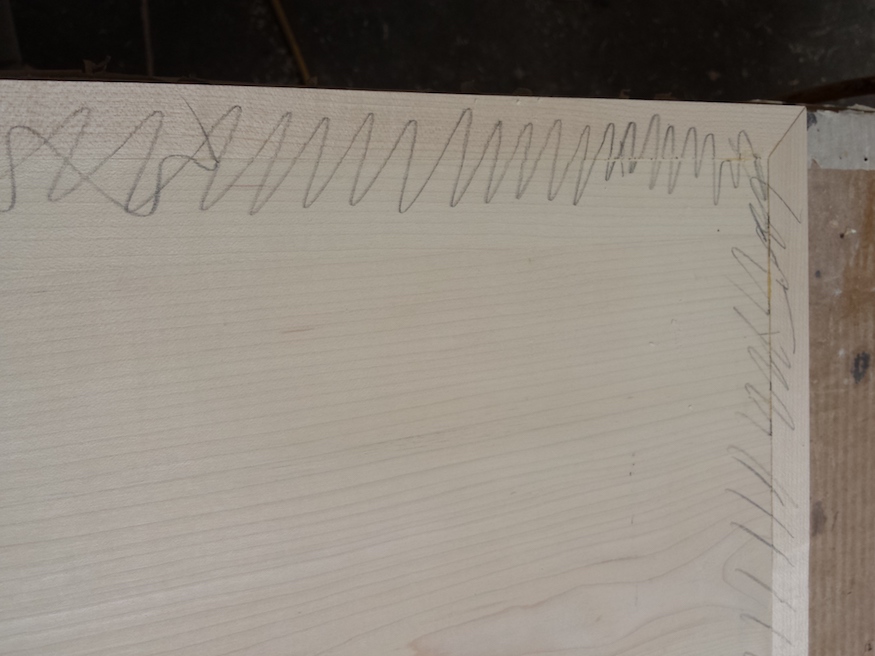

Prior to sanding them smooth, draw a series of short lines across both the top of the wood and the top of the sheet stock. A single “squiggly” line will do just fine. As you begin sanding, you must continually look at the wood and lines while using consistent pressure. Do not tilt or use the edge of the sanding instrument. By keeping your sander completely flat, there is more surface contact, thus it takes longer to remove the material. And always keep the sander moving. If you hold the sander in the same position you run the risk of burning through the veneer, exposing the core and ruining the piece.

You will notice that the lines on the wood edge will disappear first because they are at a higher level. As you continue to sand, the lines on the sheet stock will also disappear and be sanded off. STOP SANDING THAT AREA WHEN THE LINES ON THE SHEET STOCK DISAPPEAR. Continue moving the sander along the edge in a back and forth motion. When all of the pencil lines are completely gone, the wood and the veneered sheet stock will be completely smooth and they will feel as if they are one piece of material.

So next time 2 pieces of material need to be joined together, simply draw lines across the two pieces of material and when the lines are gone, it is time for the finish. Good luck!!!

Stay tuned for more woodworking tips, tricks, jigs, and techniques coming soon. In the meantime, learn more about our process or view some of our recent work in our gallery.