What is Sapele?

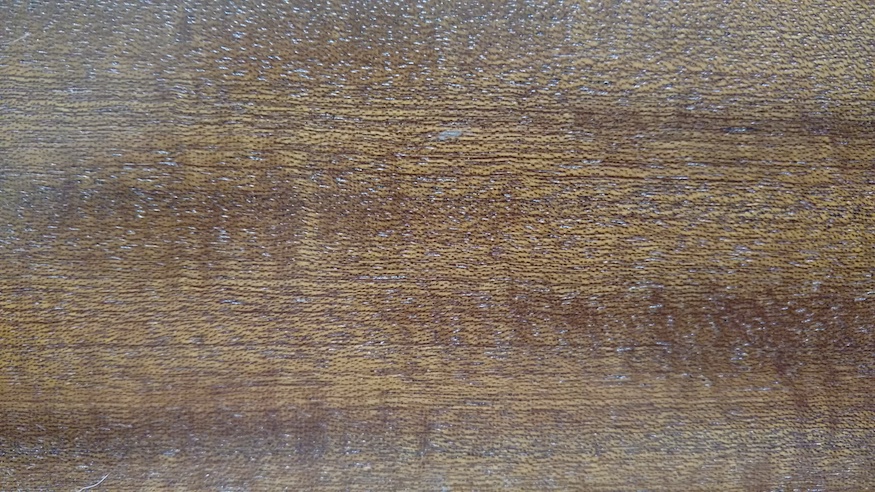

Sapele is an exotic hardwood native to tropical Africa. A relative to well known genuine Mahogany, sapele often grows to 147 feet tall and is both harder and heavier than genuine mahogany. Its heartwood is usually a golden to dark reddish brown and its sapwood is a white or pale yellow color. Both heartwood and sapwood are known to darken with age.

Sapele is known for a variety of figured grain patterns from the commonly found “ribbon” pattern to pommele, quilted, mottled, beeswing, and fiddleback patterns. Sapele’s grain is fine, uniform, interlocked, and has a natural luster. When being worked, sapele has its own fragrant and distinct, cedar scent. Due to its desirability and a 20 percent population reduction over the past several generations, sapele is now listed at a “vulnerable” status.

Why Choose Sapele?

Despite its vulnerable status, sapele is moderately priced for plainsawn and quartersawn lumber. However, getting into figured lumber and veneer can be very, very expensive – in particular, pommele or quilted Sapele are some of the most expensive types of sapele reaching nearly $140.00 per foot. Sapele is often used in veneer, furniture, cabinetry, flooring, boats, musical instruments, and small wood specialty items.

Due to its outward characteristics and export restrictions on genuine mahogany, sapele is often used as a mahogany substitute. Sapele is a bit more stable and durable than mahogany – it has excellent figure and works excellent as a more cost effective substitute. It is commonly exported and has become economically important in Africa.

Sapele in Woodworking

Sapele is not necessarily the easiest wood to work with, but it does work okay. It is fragrant and though some say it smells like cedar, we feel it smells more like ground pepper when being worked. Because of its fibrous, interlocked grain, it can be troublesome to machine, sometimes resulting in tearouts. It is a soft hardwood, so its lower density and Janca rating do help out a bit in the machining process.

Sapele turns, glues, sands, and finishes well.

It takes nails well and is soft enough to take screws, but because of its interlocked grain it is much easier to prebore holes before putting a screw in. Once in a great while we do get the opportunity to work with sapele building custom retail fixtures. Though our craftsmen have mixed opinions about working with sapele, they just can’t help but to stand back and admire its beauty in the finished product.

Like the look of Sapele? Contact us to begin planning a new custom woodworking piece for your home, office, or retail space.