A Little Bit About Steff USA

Steff USA is a woodworking machinery company that is owned by J & G Machinery, Inc. A dominant name in woodworking power feeders, Steff feeders are well known for their reliability and exceptional quality. They make power feeders, boring machines, radial arm saws, and edge banders. Steff power feeders are built and manufactured by a Maggi Engineering in Italy.

What is a power feeder?

A power feeder is a machine in itself that pushes stock through another woodworking machine at a consistent speed and pressure, both against the bed and fence of that machine. Power feeders come in various sizes and configurations, often having 2-8 wheels. Power feeders can be attached to and hooked up to a wide variety of woodworking machines and saws, helping a craftsman to create a uniform finish cut that is free of the defects that can sometimes occur with manual feeding.

Power feeders are also used to make machines that are otherwise unsafe easier and safer to use, allowing even a novice to operate woodworking machinery safely, because they eliminate the need to place hands of fingers near the cutting surface. For example, shapers are very difficult to operate and are also very dangerous. Using a power feeder is a must when using this machine and it allows the craftsman to operate the machine comfortably and efficiently without putting his limbs or phalanges at risk.

Basic Parts of a Power Feeder

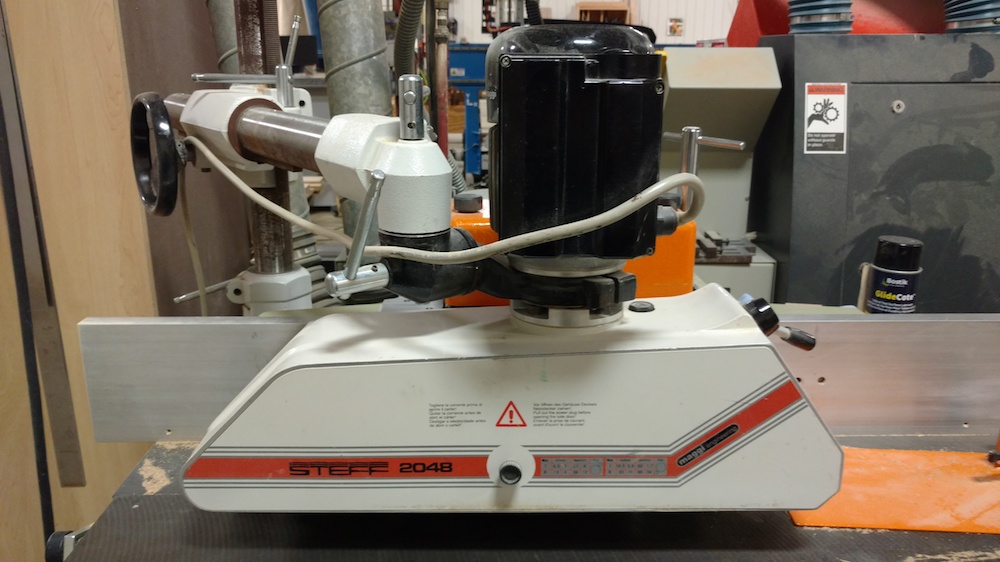

- Drive Motor – The drive motor powers the drive system

- Housing – the housing protects the drive motor, drive system, and other working parts of the machine

- Support Arm – this is what attaches the feeder to the machine. The support arm also supports the feeder.

- Rollers – these help push the material through or over the cutting edge and maintain and even, consistent pressure as it is fed through

- Drive System – this is the gearing and linkage that transfers rotational power from the drive motor to the pressure rollers

Our Steff Power Feeders

We have 4 Steff power feeders in our shop – among many other power feeders. Two are on shapers, one is on an Onsrud inverted router, and one is on our Powermatic 72 table saw. We love these feeders for a couple different reasons. Obviously, they help us maintain accurate pressure and feed rates which in turn helps us maintain a perfect cut. But the power feeders also help ensure our safety when working with less than safe machines.

The shapers can be difficult machines to run, even for a skilled craftsmen. They require the craftsman to place his fingers near the cutting edges and maintain pressure while making sometimes difficult cuts. Needless to say, even the most skilled and experienced craftsmen sometimes feel tentative when operating a shaper. The Steff (and others) power feeders eliminate the need to work right next to the cutting edges completely, allowing our craftsmen to focus on running the material and ensuring they achieve a good, clean cut.

Tune into the D.P. Juza Woods & Fixtures blog each week for an inside look at the machines that power our Shell Lake woodworking shop. For a closer look at the quality of our work, we invite you to view our recently completed pieces in our project gallery.