A Little Bit About SCMI Group

SCMI was founded in 1952 and began making wood machinery in 1976. Throughout the years, they acquired several other companies and the group still includes many brands today. SCMI Group produces a multitude of woodworking machinery including beam saws, boring machines, moulders, and sanders to name a few.

What Is A Shaper?

A wood shaper is a machine with vertical or sometimes horizontal spindle drivers that is used to cut and shape wood into a large variety of profiles for many projects that come through our shop.

When it comes to woodworking, the cost, and the space woodworkers have to utilize, shapers are often “left out” machine. Because routers can perform some of the same functions as a shaper and are cheaper and smaller, many woodworkers substitute an inverted router with a table for the shaper. However, the shaper offers its own value, quality, accuracy, and precision a router simply cannot match.

With regards to tooling, a shaper is kind of like a much more powerful version of a router. It has the capability of running much more complex profiles and can cut a complex profile in one pass, opposed to three or four passes using a router. Routers are also equipped with power feeders which move material with more evenness and pressure with a greater consistency than a human ever could.

The Main Parts Of A Shaper

Base – The base is perhaps one of the most important parts of a shaper. It acts as support for the entire machine and serves as a work area, allowing the wood being worked to lay flat. The operating controls are attached to the base bottom and the shaping is done on the top of the base, or router table.

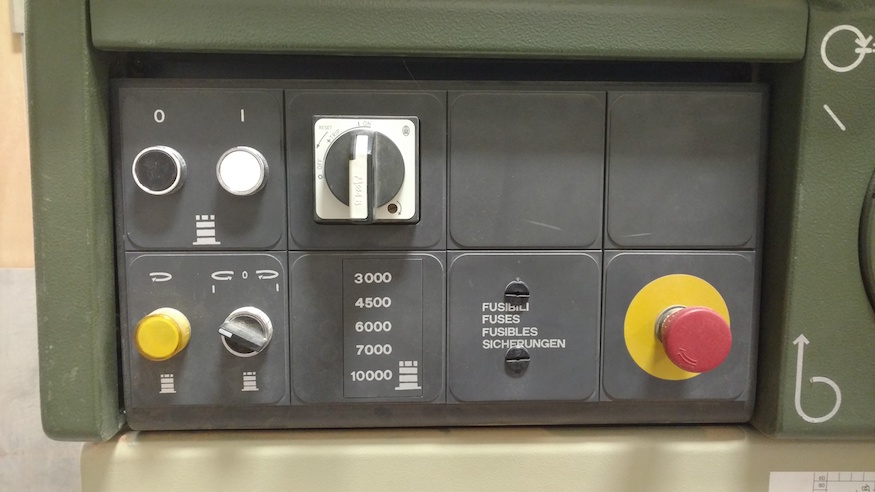

Operating Controls – Being located at the base of the machine, the foot operated controls allow the operator to manage the work without having to take his hands off the wood being run through the machine. By pushing on the controls with your foot, you can tell the machine to continue cutting, cease cutting, and can also reverse the direction in which the material can be run.

Transmission – This is attached to the base, spindle, and cutter heads and is also enclosed to help keep clear of dust. The transmission is the “motor” of the machine.

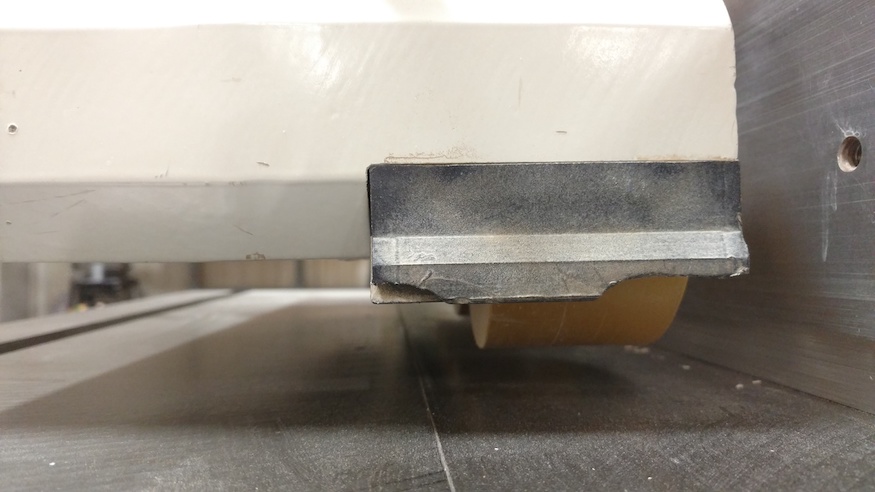

Cutter Head and Spindle – This is what does the cutting and shaping of the wood. This is the dangerous part of the machine and great care must be taken to keep fingers away from this area. The cutter head is attached to the spindle.

Guards – These help guide and direct wood through the machine. They are a safety feature and are in place so the craftsman can keep his hands clear of the cutter head.

Optional Attachments – These optional add-ons allow the machine to perform a variety of other functions. One example of optional attachments are various or additional spindles. These different spindles can cut different shapes and designs.

Our Shaper

Our SCMI T130 shaper was purchased new around 2000 and has many cool features. The foot pedal spindle break is one of the unique features on the machine, allowing the craftsman to instantly stop the machine from cutting without taking his hands away from the work. It also has a Holz four roller power feeder.

The power feeder carries the wood through the machine with an even pressure. SCMI also added to the machine 5 spindle speeds ranging from 3,000 to 10,000 rpm and three different emergency stops to increase the craftsman’s safety. The machine also displays a digital readout on the base that depicts spindle height adjustment and uses pneumatic clamps that can clamp and unclamp a spindle in a matter of seconds.

The pneumatic clamping system allows us to swap an entirely new spindle (equipped with cutters) rather than mounting and un-mounting each blade to one spindle each time a change needs to be made. Not only does this option keep transitions and setup to a minimal amount of time, it also prevents wear on each of the spindles.

The demand for our SCMI shaper in the shop is so great that we also have two others to use as backup when the SCMI is in use. Any time a job requires a complex profile, we use the shaper – which occurs within each and every one of the projects that comes through the shop. We use our shaper to create stunning custom furniture, intricate moulding and millwork, kitchen cabinets, and retail display fixtures.

Contact us to get started on a custom woodworking project of your own, or view our gallery for some inspiration.