A Little About Powermatic

Located in McMinnville, Tennessee, Powermatic Corporation officially started in 1928, building large wood planers. Nearly 90 years later and after several different owners, Powermatic Corporation is still producing woodworking machinery in its 400,000 square foot facility in LaVergne, Tennessee.

Though founder Leonard F Smith started the company by building and selling planers, Powermatic now produces many quality woodworking machines from the planer, to CNC routers, band saws, table saws, and more.

What is a Planer?

A planer is a machine or hand tool that shaves the top layer of a board in order to trim it to a desired thickness that is usually determined by the project the board is to be used for. When planing material, the craftsman must set the machine’s height adjustment to reflect the desired thickness of the board he will be planing.

Once the desired thickness is set, the board is fed into the machine where the in-feed roller grabs the board and pushes it under the rotating cutting head. As the in-feed roller continues to pass the board under the cutting head, the out-feed roller pushes the trimmed, completed section of the board out of the machine.

The Main Parts of a Planer

As with any power tool or woodworking machine, it takes many parts for a planer to function. A planer has a series of “supportive” parts from the base to the saddle, and also has several “functional” parts – like cutting heads or cross rails.

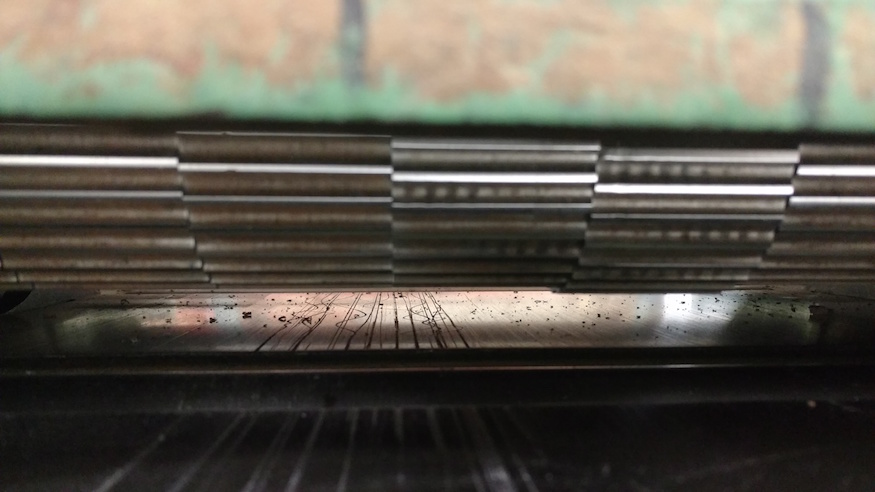

- Cross rails are used to help move and adjust the tool heads up and down, altering the depth the material is cut at. Cutting heads are what does the cutting and trimming of the wood. They contain the tool post and cutting tools/knives.

- The saddle is where the cross rail and cutting heads are fixed. There are two saddles on the machine; one for the right cutting head, and one for the left.

- The bed is a cast iron piece that lays the groundwork for the entire machine. It supports all the other parts of the machine.

- The table, a rectangular cast mount, sets atop the bed and supports the materials (wood) being cut.

- The housing is a vertical casting that straddles the table and the bed. It supports the cutting head and other components of the machine (ie. cross rails, saddle, etc.)

- In-feed and Out-feed Rollers move the wood through the machine. The in-feed roller is placed ahead of the cutting heads, and the out-feed is placed behind the cutting heads.

Our Powermatic Planer

Our Powermatic model 221 planer was built in 1965 and just might be the loudest machine in the shop. Because our first choice machine is typically our moulder, this planer doesn’t get utilized all that often, however we do use it from time to time when the moulder is already set up and running different material.

Even though it is 52 years old, this machine has been unsurpassed for its dependability and precision performance in an extremely wide variety of planing requirement. Powermatic incorporated maximum efficiency by utilizing every modern safety feature available and its power feed control allows the operator to feed 20-50 feet of material per minute.

Over the last 20 years, we have crafted more than 100,000 unique and stunning wood pieces using machines like this one. Contact us to get started on your own custom woodworking project with the D.P. Juza team.