How we ensuring safe delivery of our custom cabinets and fixtures to any location

Ensuring our clients receive their custom cabinets and fixtures in ideal condition is just as important as building them precisely. That’s why every custom cabinet and fixture goes through our protection process. We do this before loading them into company trailers or shipping containers, based on where they are going.

We carefully prep each piece to ensure that it reaches the client in the same high-quality condition it left the shop. No matter the destination.

Fixtures with delicate surfaces or those shipped overseas go through our protection process. The fixtures pictured in this article are bound for a client in the Bahamas.

Our Protection Process

We start our protection process by cleaning and inspecting each fixture to ensure all parts are in place and secure.

Then the fixture has foam sheeting applied to all painted surfaces.

When the foam is in place, we cut and tape strong cardboard protectors onto the fixtures.

Then, we tightly wrap each piece in plastic to hold the protection layers together.

Throughout this process, we inspect each piece to ensure the protection layers are suitable and secure. DPJ craftsmen help each other out in moving heavy fixtures or in completing tasks that go quicker with two sets of hands.

After wrapping the fixture, we label each one to identify its specific purpose. This makes it easier to identify the fixtures in their protection layers.

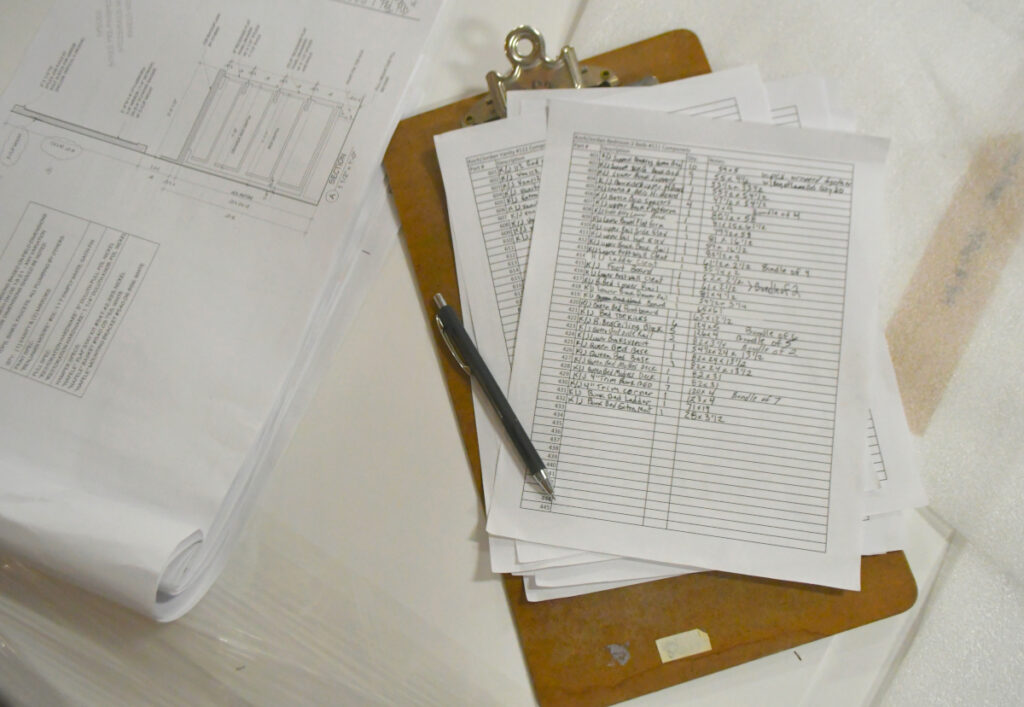

When we ship a project overseas, we use a manifest of all the fixtures to account for each piece. At the destination, the installation crew uses the manifest to correctly identify specific fixtures according to their label.

After a fixture has gone through the protection process, we place it in a designated staging area until loading begins.

Loading custom cabinets and fixtures for delivery

Loading the fixtures for transport is a bit like the puzzle game Tetris. There are different sizes, but they all need to fit together well. This helps prevent shifting and damage during transport.

We wheel large fixtures, like cabinets, into the shipping container on a dolly and then move them into place. We position painted pieces so that their painted sides, with the protection layers, face each other.

During the loading process, we consider the size of each fixture to best fill the space.

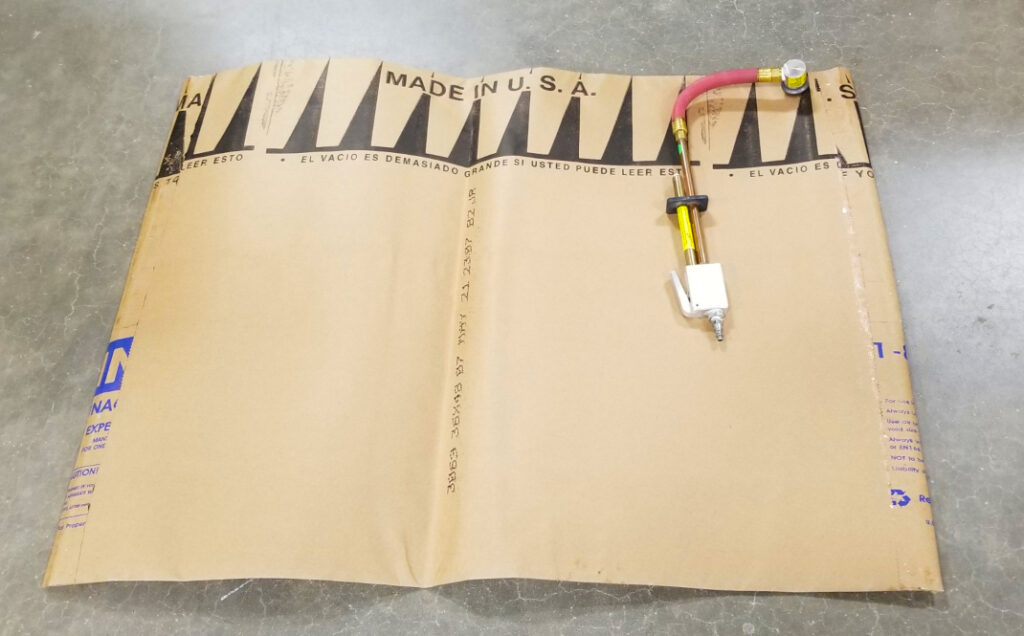

When loading a shipping container, we use dunnage bags when necessary to fill spaces between fixtures. We inflate the dunnage bags with air and place them between fixtures to limit their movement during transport.

The goal is to ensure our clients receive their fixtures in ideal condition. We pride ourselves on crafting and delivering high-quality custom cabinetry and fixtures no matter the client’s destination.