A Little Bit About Cehisa

Cehisa was founded in 1956 and since 1968 has become a world renowned edgebanding machinery company. In fact, Cehisa is the most sold brand of edgebanding machine in the United States alone. Based out of Barcelona, Cehisa also produces beam saws and drilling machines.

What Is An Edgebander?

Not all woodworking projects are made of solid wood, or solid stock. Some projects, such as cabinets, shelving, or fixtures are often made of a sheet stock material.

Sheet stock that we might use can include particle board, plywood, or MDF. To make these projects more asthetically appealing, we apply what is called “edgebanding”, or a thin veneer-like strip of wood, to the edges of the sheet stock with the core exposed.

Edgebanding certainly adds visual appeal to a product but also serves as additional durability. An edgebander is the machine that applies the edgebanding to the substrate.

How does an edgebander work?

The material is fed into one end of the machine and is supported by an apron. On the back side of the machine, working parts pull the banding, apply a hot melt adhesive, and stick it to the material that was fed into the front side of the machine.

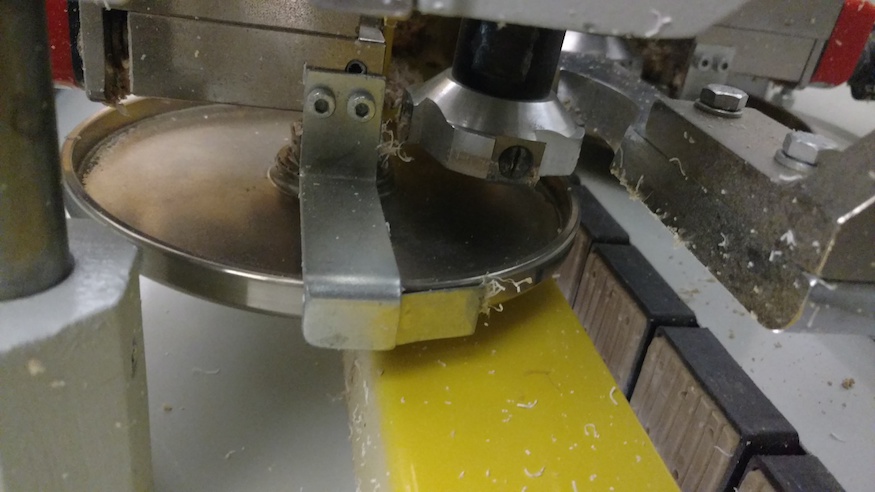

Once the edge banding has been adhered to the material, several trimming stations remove excess banding off the front and back, and top and bottom. It then enters the polishing section of the machine and is then pushed through the outfeed where it is received by the craftsman.

Parts Of An Edgebander

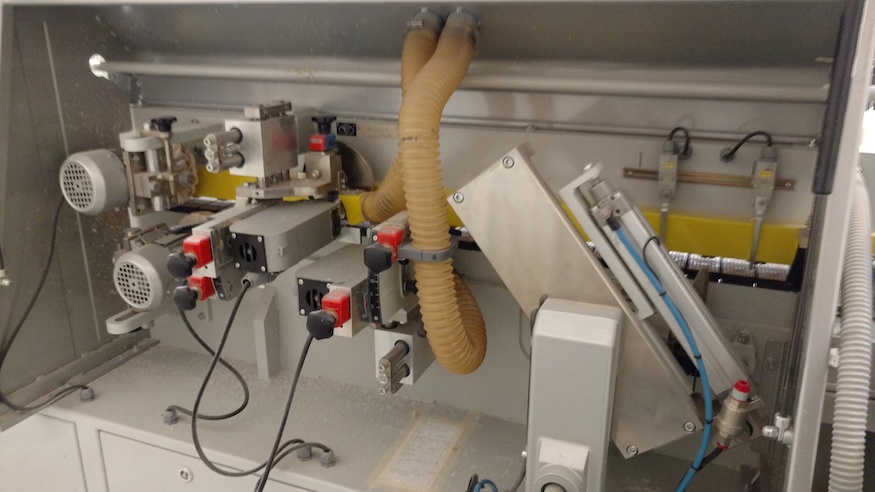

From working parts to adjustment knobs and switches and even working rollers…. There are literally hundreds of parts of an edgebander. These numerous parts are grouped into “working stations”, which are the main functions of the machine.

There are six different working stations within our edgebander:

Glue Pot Station – This heats and holds the adhesive and dispenses the adhesive onto the passing material using a roller. It controls the thickness of the adhesive that is applied to the dispensing roller and dispenses the exact amount of adhesive needed onto a variety of different size material – without any extra regulation!

Roller Base Station – Consists of three rollers and three regulators that adjust the pressure each roller exerts. The first roller, under tension, pushes the edging to panel. The second roller is tilted to give additional pressure to the top edge of the banding, and the third roller is angled in the opposite direction which gives additional pressure to the bottom edge of the banding.

V-6 End Trimming Station – This is driven by a high frequency motor and trims off surplus edging band at each end (front and back) of the material

Trimming Station – Similar to the end trimming station, the trimming station trims off surplus edging, but from the top and bottom of the material rather than the ends of the material

Scraper Station – Removes the small undualtions left by the trimmers. This helps to provide an even finish throughout the length of material.

Polishing Station – Run by two motors that are fitted with a variety of polishing cloths that adapt to the requirements of each job.

Our Edgebander

Our Cehisa edgebander was purchased new in 2013 and replaced our old Ott edgebander, which had over 150,000 hours run time on it!

We use it on a regular basis for frameless kitchen cabinets, tables, counter tops, shelving, retail displays and base cabinetry, and more. Due to the fact that the learning process is so extensive, we only have a few craftsmen that run this machine.

It features a compact hot melt EVA glue system and automatic roll cutter, strip and coil feed, and has a feed rate of 33 feet per minute. Our Cehisa has far out performed the Ott and has helped to greatly increase our quality, precision, and consistency when it comes to edge banding.

Contact us to get started on a custom woodworking project of your own, or view our gallery for some inspiration.