Common Misconceptions with Sealing Wood

A common misconception is that a special finish is required to seal wood. While commercially prepared wood is indeed available for purchase, the first coat of any finish can be used as sealer as well. Once the sealer or the first coat of finish is applied and cured, it becomes impenetrable by liquids – including the next coat of finish.

Another common misconception is that sealer provides a base for better finish adhesion. The soap in the sealer actually weakens the finish to wood bond. Often times this comes from confusion in the difference between sealer and primer. Paints, for example, have so much pigment that there can’t possibly be enough binder added to get the paint to stick to the wood.

Primer is less pigmented, so it contains more binding agents and can bond to the wood. Clear finishes are all binder and perfectly bond to the wood on their own. Thanks to misleading marketing, widesapread confusion about sealer and the sealing process is intensified. Some sealers marketed as “self-sealing” can easily lead consumers to believe that other finishes might need a separate sealer, when in reality, the “self-sealing” typically means that sealer is easy enough to sand.

There are special sealers that are available to help the sealing process provide a better end finish and to help the sealing process along more efficiently. These products make seal sanding easier, reduce grain rising of the wood, “seals off” oils, resins, or odors in the wood, and also lengthens the amount of time a finisher must apply two part finishes.

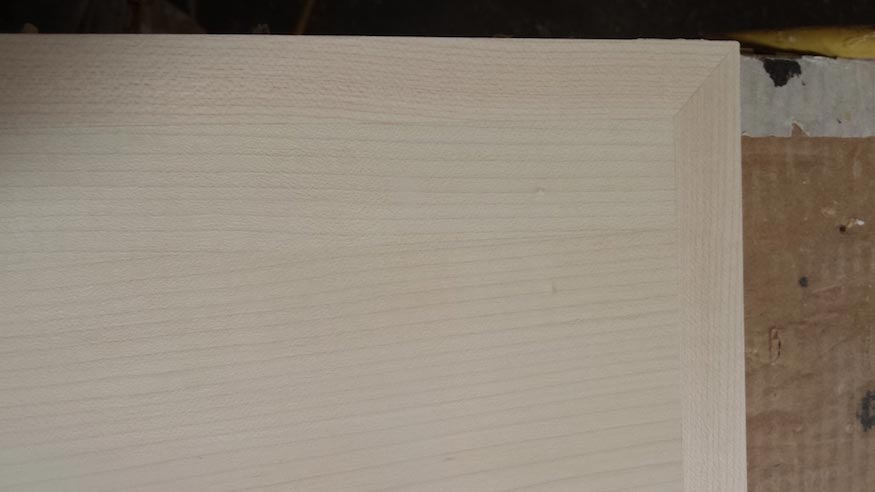

The first coat of finish, or sealer, is rough and gives great practice in the art of sanding. Sanding the rough away from the sealer creates a smooth surface that allows all the additional coats of finish to be applied smoothly for a better end product. Because varnish and lacquer can be difficult to sand, we use sanding sealer instead of finish to seal the wood.

Sanding sealer is either a varnish or lacquer that has a mineral soap additive. This soap additive makes the sealer powder when it is sanded and prevents clogging of the sandpaper in the process. When using sealer though, it is important to apply it in an appropriate thickness. Sealer that is applied too thick or in multiple coats tends to crumble or turn white if it is hit or bumped with blunt objects – even after a top coat has been applied.

Refinishing wood can be tricky for many reasons.

There may be oil or wax on furniture from polish or there may be foul odors trapped in the wood from smoke or animal urine. In refinishing, “sealing” has a little different meaning and is usually accompanied by “off” or “in”. This can also apply to new-wood finishing as well when dealing with knots in pine that often cause bonding or drying problems. To prevent fisheye, weak bonding, or other problems associated with oil, wax, or odors in wood, shellac is the answer in sealing off.

Unfortunately, shellac has mistakenly become known as a great sealer for all finishing situations and is often thought of more as a sealer than a finish. Unless there is something in the wood that can cause a problem, there is no reason to use shellac as a sealer. Applying one finish over another (like shellac) creates risk of wrinkling, poor bonding, and blistering. It can also weaken the overall finish. If something does need to be sealed off, it is best to use dewaxed shellac.

Once the sealer has been applied, it is time to sand away and prepare for the final step of the finishing process!