At DP Juza most of our custom cabinet doors start out in the shaker style, with a mortise and tenon joint.

Each cabinet door features a center panel, with rails on the top and bottom and stiles on either side. The pictured door above also has a bead, a rounded piece of wood, that is added to door fronts for aesthetics.

Measure Twice, Cut Once

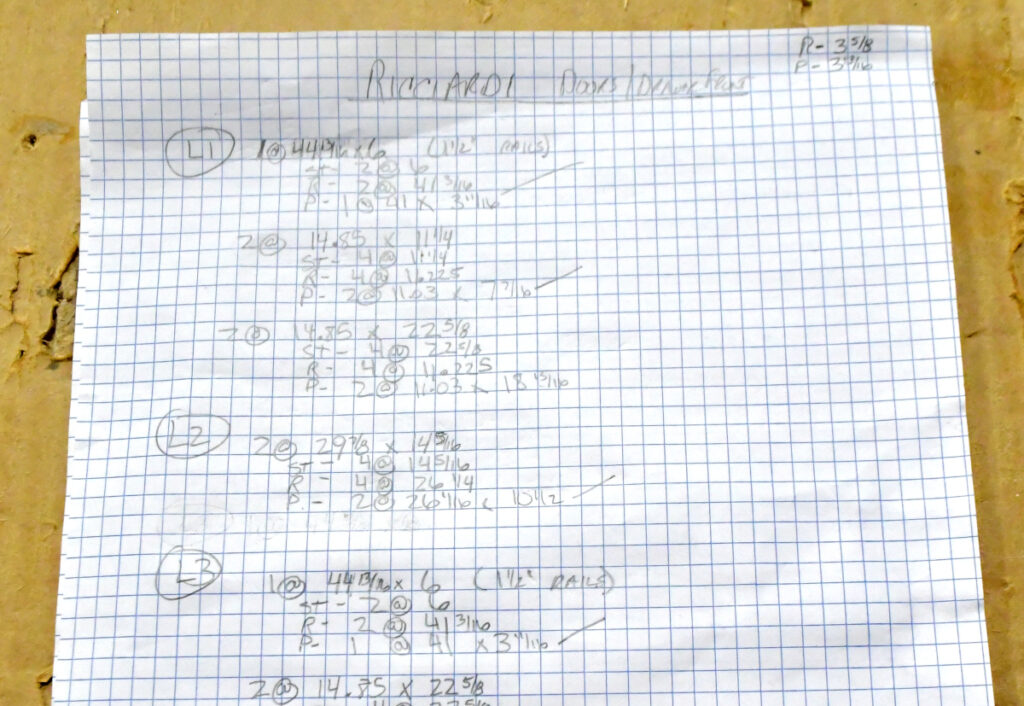

Our woodworkers confirm what cutter to use, and the dimensions listed on the project print. After confirming print sizes, the woodworker references the print to size all the cabinet doors.

We always cut our cabinet door pieces so the wood grain matches from top to bottom and side to side. We achieve this by cutting the pieces of the door from the same sheet of wood. This results in an aesthetically pleasing finished piece.

Two woodworkers independently size all the doors to double-check their measurements, ensuring they both have the correct sizes. A woodworking makes a cut list after the correct sizes are established.

Organization Key

Organization is important in this process, as many individual pieces are required to make doors for one cabinet fixture. For instance, a fixture with six doors requires 54 pieces, as each door has nine parts.

To aid in organization, our woodworkers keep the stiles and rails separate and labeled for easy reference. They first cut the stiles to size, double-checking the cuts for accuracy.

The rails are cut so they fit into the stiles. The stiles and rails are cut on separate shaper machines, one shaper is set up with a coping shield for the rails. This ensures safety for the woodworker and precision cuts to the rails.

QT along the way

When the stiles and rails are all cut, the panels are then cut to size for each door. Then doors are assembled on a bench, like on the cabinet, to ensure the correct fit and size.

After cutting all the pieces, a woodworker sands the panel and assembles it using a door clamp machine. They glue the joints and clamp each door for 5 to 7 minutes each. After clamping, they clean off the excess glue and sand the door again.

The woodworkers check the door size for accuracy, especially along the diagonal, to ensure each door is square. An unsquared door can affect an entire cabinet’s appearance, making accuracy paramount in the millwork phase before assembly.

At left, is an un-sanded maple door waiting for paint, at right, is a finish sanded cherry door waiting for stain. Our woodworkers consider the final finish of the doors during the build process, as different finishes require varying levels of pre-finish sanding. For example, paint highlights defects more than stain.