A Little About Makita

Makita Corporation is a power tool manufacturer that was founded on March 21, 1915 in Nagoya, Aichi, Japan. Today, Makita has factories in Brazil, Canada, China, Japan, Mexico, Romania, the UK, Germany, and the United States.

In 1969, Makita introduced the first rechargeable power tool and has remained on the cutting edge of power tool development since.

What is a planer?

There are two machines/tools that are commonly paired together in woodworking: a jointer and a planer. All too often, these machines get confused with one another.

A jointer is used to create flat, smooth surfaces on all four sides of a board. A planer is the machine that cuts a board down to a desired or specified thickness by shaving off the top surface of the wood.

Typically, a woodworker will run a board through the jointer first; ensuring each side or edge of the board is flat, and parallel to its opposing side. After a board has been sent through the jointer, it then goes into the planer, where a cutting head trims off the top side of the board to the desired thickness set by the woodworker.

When planing material, we first need to determine how thick our material needs to be and then make the necessary adjustments to the cutting heads or planing platform. Once the cut depth is set, the operator feeds the material into the front of the machine.

The “in-feed” roller grips the material and pushes it under the cutting drums, or the knives that trim the top of the material. After the material passes under the cutting drums, it reaches the “out-feed” roller, which pushes the trimmed section of the board out of the machine.

The main parts of a planer

As with any power tool or woodworking machine, it takes many parts for a planer to function.

A planer has a series of “supportive” parts from the base to the saddle, and also has several “functional” parts – like cutting heads or cross rails. Cross Rails are used to help move and adjust the tool heads up and down, altering the depth the material is cut at. Cutting Heads are what does the cutting and trimming of the wood. They contain the tool post and cutting tools/knives.

The saddle is where the cross rail and cutting heads are fixed. There are two saddles on the machine; one for the right cutting head, and one for the left. The bed is a cast iron piece that lays the groundwork for the entire machine. It supports all the other parts of the machine. The table, a rectangular cast mount, sets atop the bed and supports the materials (wood) being cut.

The Housing is a vertical casting that straddles the table and the bed. It supports the cutting head and other components of the machine (ie. cross rails, saddle, etc.) Infeed and Outfeed Rollers – move the wood through the machine. The infeed roller is placed ahead of the cutting heads, and the outfeed is placed behind the cutting heads.

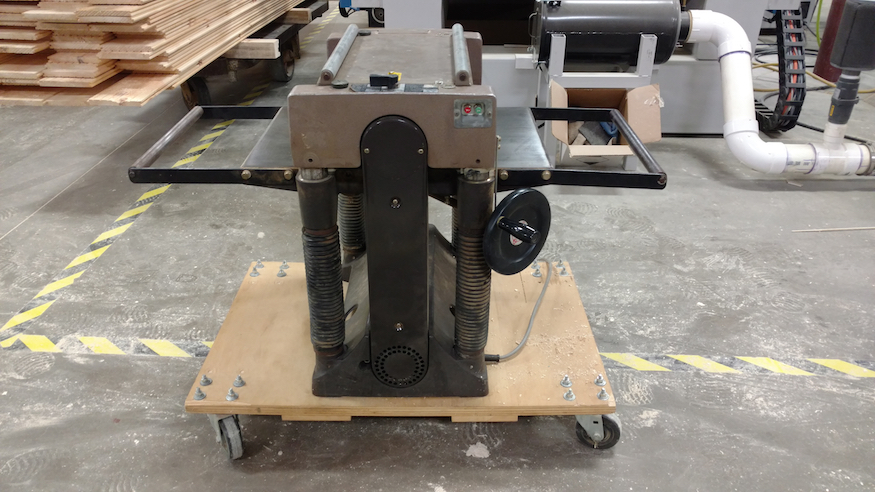

Our Makita Planer

The Makita planer allows us to take rough boards and level their thickness per specific project requirements. This means we can get material of any thickness and reduce the hassle and cost involved in ordering custom thickness material from our suppliers. By using the planer, we can also ensure our material is truly flat and level with even thickness throughout the board which aids in maintaining the high quality product our clients expect.

Thanks to the mobility of this planer, it makes its way around the shop throughout the week and has become known as “the travelling planer”. Its simplicity allows for quick setup, and its workhorse attributes allow us to plane any material necessary with ease.

Though our Makita planer is an older machine, it is a great machine that produces well cut material, so we do still use it on a regular basis with smaller scale projects, or if our moulder is already set up and running material for another project.

Want to learn more about the machines we use everyday in the shop? Follow us on Facebook for the latest updates from the D.P. Juza Woods & Fixtures blog.